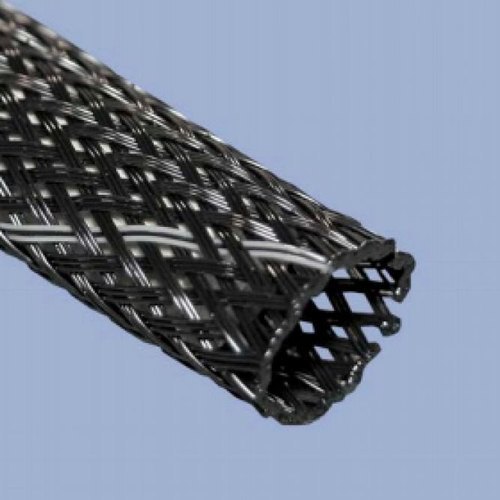

Polyester Expandable Braided Sleeves

25 INR/Meter

Product Details:

- Product Type Sleeve

- Material Polyester

- Color Black

- Click to view more

X

Polyester Expandable Braided Sleeves Price and Quantity

- 25 INR/Meter

- 1 Meter

Polyester Expandable Braided Sleeves Specification

- Black

- Polyester

- Sleeve

Polyester Expandable Braided Sleeves Trade Information

- MUMBAI

- Cash in Advance (CID)

- 500000 Meter Per Month

- 1 Days

- Yes

- Free samples are available

- 100m per roll

- Australia South America Eastern Europe Western Europe Middle East Africa Central America Asia North America

- All India

- ROHS/CE/UL

Product Description

Polyester expandable braided sleeves are protective covers produced from polyester fibres that are braided into a flexible and expanding tube-like structure. They are also known as cable sleeves or simply expanded sleeves. These sleeves are made to offer a variety of advantages, such as cable management across different industries, abrasion resistance, and cable organisation.

Expandable braided sleeves made of polyester are normally made from high-quality polyester fibres that are securely braided together. A flexible and expanding structure that can support wires, cables, or hoses of various diameters is produced by the braiding process.

Polyester Expandable Braided Sleeve Characteristics:

1. Cable Management: Managing and organising cables, wires, and hoses is one of the main purposes of these sleeves. The sleeve may be expanded to accommodate cables of various diameters, giving it a tidy and organised appearance.

2. Protection Against Abrasion: The braided polyester fabric provides reliable defence against abrasion, friction, and small impacts. It contributes to extending the lifespan of delicate cables and wires by protecting them from damage.

3. Flexibility: The braided sleeve's natural adaptability makes it excellent for moving applications, such as those in robotics, automotive systems, and industrial machines.

4. Heat Resistance: Polyester expandable braided sleeves are frequently heat-resistant, making them appropriate for usage in settings where high temperatures are a problem.

5. Simple Installation: These sleeves' expandability makes installation simple. They don't require complicated or time-consuming installations because they can simply be slipped over cables or wires.

6. Aesthetic Improvement: The braided sleeve's homogeneous appearance gives cable assemblies and wire bundles a neat, well-organized appearance that improves their aesthetic appeal.

7. Expandability: The sleeves' expandable design enables for both contraction and expansion to fit a variety of cable sizes, making them extremely adaptable for a variety of applications.

Applications of Polyester Expandable Braided Sleeve:

Polyester expandable braided sleeves are used in a variety of fields, including:

1. Electrical engineering and electronics

2. Automobile wiring looms

3. Aviation and space

4. Industrial automation and machinery

5. Control of cables in homes and offices

Installation of Polyester Expandable Braided Sleeve:

Installing the sleeves is as easy as slipping them over cables or wires because they are user-friendly in design. Some sleeves contain a lengthwise aperture that enables them to be wrapped around existing cable assemblies without requiring the cables to be disconnected.

Physical Properties of Polyester Expandable Braided Sleeves:

| Material | PET monofilament |

| Working Temperature | -40??? to150??? |

| Melt Point | 240+(-)10??? |

| Flammability | VW-1 |

| Standard Color | Black, Grey, White |

| Available Color | Over 60 available options |

| Certification | UL, ROHS, Reach, Halogen free |

| Cutting Tool | Hot Knife |

Specification of Polyester Expandable Braided Sleeves:

| Part No | Size | Thickness | Expanded Range |

Standard Color |

Packing | ||

| Inch | mm |

Min(I) |

Max(O) |

(m/spool) | |||

| MJ-PEBS003 | 1/8" | 3mm | 0.25mm | 1mm | 6mm |

Black Grey White |

1000m |

| MJ-PEBS006 | 1/4" | 6mm | 3mm | 9mm | 500m | ||

| MJ-PEBS008 | 5/16" | 8mm | 5mm | 12mm | 350m | ||

| MJ-PEBS010 | 3/8" | 10mm | 7mm | 17mm | 350m | ||

| MJ-PEBS012 | 1/2" | 12mm | 8mm | 20mm | 300m | ||

| MJ-PEBS016 | 5/8" | 16mm | 10mm | 27mm | 250m | ||

| MJ-PEBS020 | 3/4" | 20mm | 14mm | 30mm | 200m | ||

| MJ-PEBS025 | 1" | 25mm | 18mm | 33mm | 200m | ||

| MJ-PEBS032 | 1-1/4" | 32mm | 20mm | 50mm | 150m | ||

| MJ-PEBS038 | 1-1/2" | 38mm | 30mm | 60mm | 100m | ||

| MJ-PEBS045 | 1-3/4" | 45mm | 35mm | 75mm | 100m | ||

| MJ-PEBS050 | 2" | 50mm | 40mm | 80mm | 100m | ||

| MJ-PEBS064 | 2-1/2" | 64mm | 45mm | 105mm | 100m | ||

| MJ-PEBS076 | 3" | 76mm | 64mm | 120mm | 100m | ||

FAQs of Polyester Expandable Braided Sleeves:

1. What are the uses of polyester expandable braided sleeves?

Ans: Cables, wires, and hoses are arranged and safeguarded using expandable braided polyester sleeves. In applications ranging from electronics to industrial machinery, they offer abrasion resistance, cable management, and a neat look.

2. How do these sleeves protect cables?

Ans: A flexible and strong sleeve that protects wires from abrasion, friction, and small impacts is made from tightly braided polyester fibres. Sensitive cables and wires' lifespan is increased by this protection.

3. What sizes do Polyester Expandable Braided Sleeves come in?

Ans: These sleeves come in a range of sizes to fit a variety of cable diameters. There is a size appropriate for the majority of uses, from lightweight machinery to compact electronics.

4. Are these sleeves simple to put on?

Ans: The installation process is simple. The sleeves may be effortlessly put over cables or wires thanks to their expanding shape. Some sleeves have an aperture down the middle that can be used to wrap around existing cable assemblies without disconnecting the cables.

5. What sectors are Polyester Expandable Braided Sleeves most frequently used in?

Ans: These sleeves have uses in a wide range of sectors, including cable management in homes, industrial automation, automotive, aerospace, and electronics production. These sleeves are useful anywhere cable organisation, protection, and aesthetics are important.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese