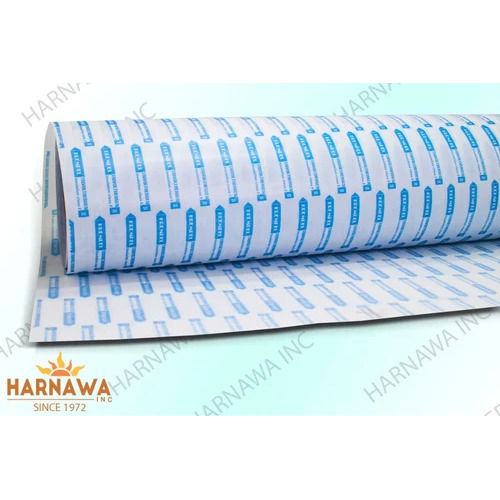

Fiberglass Sleeving B Class

15 INR/Meter

Product Details:

- Color White, Black, Red, Yellow

- Product Type Sleeving

- Material Fiberglass

- Click to view more

X

Fiberglass Sleeving B Class Price and Quantity

- 4 Meter

- 15 INR/Meter

Fiberglass Sleeving B Class Specification

- White, Black, Red, Yellow

- Fiberglass

- Sleeving

Fiberglass Sleeving B Class Trade Information

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India

Product Description

Fibreglass sleeving is a form of insulating material used in electrical and electronic applications and is frequently categorised as B-class insulation. In order to improve its electrical and thermal insulation capabilities, it is often formed from braided or woven fibreglass fibres.

Fiberglass Sleeving B Class Features:

1. B-class fibreglass sleeving is made to endure high temperatures, which are frequently in the 130 to 155 degree centigrade range. Because of this, it can be used in situations where heat resistance is important.

2. Providing electrical insulation is one of the main functions of fibreglass sleeving. It can isolate and shield electrical lines and components from electrical currents thanks to its high dielectric characteristics.

3. Fibreglass sleeving is adaptable and can follow the contours of wires and cables, making it ideal for use with irregularly shaped objects and in small places.

4. It provides good abrasion resistance, preventing wear and tear on wires and cables, especially in dynamic or high-friction settings.

5. B-class fibreglass sleeving can be used in a number of industrial and automotive applications since it is frequently resistant to common chemicals and solvents.

6. Although not fireproof by nature, B-class fibreglass sleeving can provide some flame resistance and can slow the spread of flames in electrical systems.

Fiberglass Sleeving B Class Benefits:

1. The improvement of electrical safety is the main advantage of B-class fibreglass sleeving. It lessens the possibility of short circuits, electric shocks, and fires by keeping electrical lines away from other conductive materials.

2. Fibreglass sleeving's capacity to provide thermal insulation helps maintain the integrity of electrical cables and components, extending their lifespan and reliability, especially in hotter situations.

3. Due to its adaptability and temperature resistance, it may be utilised in a variety of applications, including motor winding, the manufacture of transformers, automobile wiring harnesses, and industrial equipment.

4. Installation is rather simple for fibreglass sleeving. It can be used to cover wires or other components, and ties or adhesive tape can hold it in place.

5. B-class fibreglass sleeving frequently offers a cost-effective option for electrical insulation needs when compared to alternative high-temperature insulating materials.

6. A variety of fibreglass sleeving varieties are compliant with safety rules and industry standards, guaranteeing that your electrical systems are secure.

FAQs of Fiberglass Sleeving B Class:

1. What sets B-class fibreglass sleeving apart from other forms of insulating material?

Ans: The insulating material known as B-class fibreglass sleeving is largely employed in electrical and electronic applications. It is made to endure temperatures typically between 130 and 155 degree centigrade. It stands out for its capacity to offer thermal and electrical insulation while satisfying particular temperature and voltage specifications.

2. What are the typical uses for B-class fibreglass sleeving?

Ans: Several applications, including the insulation of motor windings, transformers, automobile wiring harnesses, and industrial machinery, frequently make use of B-class fibreglass sleeving. It is used in high-temperature conditions wherever electrical and thermal insulation is needed.

3. How can I choose the best B-class fibreglass sleeving for my project?

Ans: Consider parameters like the needed temperature rating, voltage class, diameter, and application specifications when selecting the best B-class fibreglass sleeving. In order to achieve safe and efficient insulation, it is essential to match the sleeving's qualities with the requirements of your project.

4. When employing B-class fibreglass sleeving in electrical applications, what are the main advantages?

Ans: The main advantages of using B-class fibreglass sleeving include increased electrical safety due to insulation, increased longevity and dependability of electrical components, versatility in a wide range of applications, cost-effectiveness in comparison to other high-temperature insulating materials, and compliance with industry standards and safety regulations.

5: Is B-class fibreglass sleeving fireproof or flame resistant?

Ans: B-class fibreglass sleeving can provide some flame resistance even if it is not intrinsically fireproof. It adds another layer of safety and may assist slow the spread of flames in electrical systems. The sleeving must, however, be confirmed to meet all applicable fire safety standards and laws in locations where fire resistance is crucial.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese