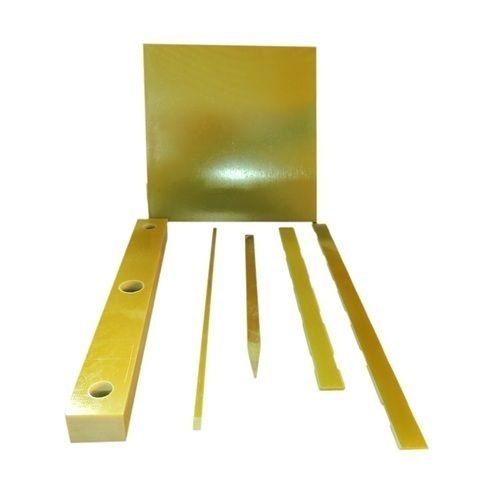

Glass Epoxy Sheet FR4

Product Details:

- Size 1030 mm X 1230 mm

- Product Type Epoxy Sheet

- Usage Electrical Appliances

- Color Yellow

- Material Glass Epoxy

- Click to view more

Glass Epoxy Sheet FR4 Price and Quantity

- 100 Kilograms

- 220 INR/Kilograms

Glass Epoxy Sheet FR4 Specification

- 1030 mm X 1230 mm

- Electrical Appliances

- Glass Epoxy

- Yellow

- Epoxy Sheet

Glass Epoxy Sheet FR4 Trade Information

- Mumbai / Bhiwandi

- Delivery Point (DP) Paypal Cash Against Delivery (CAD) Telegraphic Transfer (T/T) Cash in Advance (CID) Cheque Cash Advance (CA)

- 4000000 Kilograms Per Month

- 1 Days

- Free samples are available

- Wooden pallets

- Australia North America South America Eastern Europe Western Europe Middle East Africa Central America Asia

- All India

- CE & RoHS

Product Description

The widely used thermosetting epoxy laminate material Glass Epoxy Sheet FR4, usually referred to as FR4, is renowned for its remarkable electrical insulating characteristics. Applications involving electronics and electricity frequently employ it.

These are its main attributes and advantages:

1. Material Composition: Woven glass fabric is impregnated with epoxy resin, which is then used to create FR4 before curing it at a high temperature and pressure. This procedure produces a strong and long-lasting substance.

2. Outstanding Electrical Insulation: One of FR4's key characteristics is its exceptional electrical insulation capabilities. It is suitable for use in applications where electrical isolation is essential due to its high dielectric strength.

3. Flame Retardant: Because FR4 is made to be flame retardant, it has the ability to extinguish itself. It is a secure option for electrical and electronic equipment because it does not assist combustion and will not help a fire spread.

4. High-Temperature Resistance: This substance can endure high temperatures without noticeably deteriorating its electrical or mechanical qualities. Some electronic components require it because it is stable and dependable in hot temperatures.

5. Mechanical Strength: FR4 has good dimensional stability and mechanical strength. It can tolerate physical impact, vibration, and mechanical stress without easily breaking or deforming.

6. Chemical Resistance: It is resistant to a wide range of chemicals, including acids and solvents. Acid and solvent resistance makes it appropriate for use in applications where exposure to corrosive substances is a concern.

7. Low Water Absorption: The electrical and mechanical performance of FR4 is guaranteed to be maintained even when it is exposed to moisture for an extended period of time due to its low water absorption capabilities.

Glass Epoxy Sheet FR4 Benefits:

1. Versatility: Glass Epoxy Sheet FR4 is versatile and has a wide range of uses, including electrical insulators, connectors, printed circuit boards (PCBs), and more.

2. Reliability: It is a dependable option for electrical and electronic components, delivering consistent performance over time because to its high electrical insulation and thermal resistance.

3. Safety: Applications where fire prevention is crucial, such electrical panels and control systems, benefit from FR4's flame-retardant qualities.

4. Durability: It has a long service life, eliminating the need for regular replacements and maintenance, thanks to its resilience to environmental variables and good mechanical qualities.

5. Ease of Fabrication: The manufacturing process for electronic components is made simpler by the ease with which FR4 may be machined, drilled, cut, and shaped to fulfil specific design requirements.

6. Cost-Effective: Despite having a greater initial cost than certain other materials, its durability and long-term performance lower the overall cost of ownership, making it more cost-effective in the long run.

Glass Epoxy Sheet Property Data :

|

Technical Data |

Method of Verification |

Unit |

3240 |

|

I.Physical Properties |

|

|

|

|

Density |

ISO 1183 |

g/cm3 |

2.0-2.1 |

|

Water absorption 24hrs |

ISO 62 |

% |

0.05-0.15 |

|

III.Thermal Properties |

|

|

|

|

Max. service temperature -Short term |

ISO 75-2 |

Degree Centigrade |

|

|

Max. service temperature - Long term |

ISO 75-2 |

Degree Centigrade |

130-140 |

|

Coefficient of Thermal Expansion-LW |

ISO 11359 |

m/K |

|

|

Coefficient of Thermal Expansion-CW |

ISO 11359 |

m/K |

|

|

Thermal Conductivity |

ISO 11359 |

W/(m,K) |

2.2-2.5 |

|

Flammability |

UL 94 |

Class |

V-1 |

|

II.Mechanical Properties |

|

|

|

|

Tensile strength at yield |

ISO 527-2 |

MPa |

220 |

|

Tensile strength at break |

ISO 527-2 |

Mpa |

|

|

Hardness Rockwell |

DIN 53505 |

|

120-125 |

|

Izod impact strength |

ISO 179 |

kJ/m2 |

33 |

|

Bending Strength |

ISO 527-2 |

Mpa |

|

|

Flexural strength-LW |

ISO 179 |

Mpa |

314 |

|

Flexural strength-CW |

ISO 179 |

Mpa |

216 |

|

Adhesive Strength |

ISO 179 |

|

5600 |

|

Compression strength-LW |

ISO 179 |

Mpa |

350 |

|

Compression strength-CW |

ISO 179 |

Mpa |

147 |

|

IV.Electrical Properties |

|

|

|

|

Volume resistively |

IEC 60093 |

Ohm () * cm |

1.3x1014 |

|

Surface resisively |

IEC 60093 |

Ohm () |

3.5x1012 |

|

Electric strength- LW |

VDE 0303 |

kV/mm |

14.2 |

|

Breakdown Voltage-CW |

VDE 0303 |

kV |

>34 |

|

Relative dielectric coefficient |

VDE 0303 |

|

4.7 |

|

Dielectric Loss mudule |

VDE 0303 |

50HZ |

0.04 |

|

Arc resistance |

VDE 0303 |

|

|

FAQ:

1. What exactly is FR4 Glass Epoxy Sheet?

2. What applications are there for Glass Epoxy Sheet FR4?

3. Why is utilising Glass Epoxy Sheet FR4 for PCBs advantageous?

4. How is FR4 Glass Epoxy Sheet manufactured or crafted?

5. Is Glass Epoxy Sheet FR4 safe for the environment?

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese