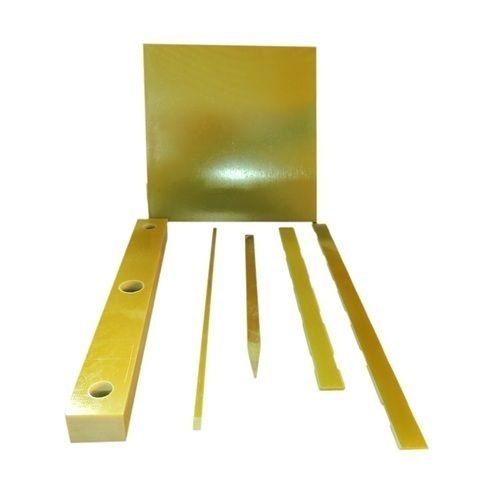

Glass Epoxy Sheet 3240

22 INR/Meter

Product Details:

- Product Type Epoxy Sheet

- Size 1020mm x 2020mm (L x W)

- Material Glass Epoxy

- Click to view more

X

Glass Epoxy Sheet 3240 Price and Quantity

- 22 INR/Meter

- 1 Meter

Glass Epoxy Sheet 3240 Specification

- 1020mm x 2020mm (L x W)

- Epoxy Sheet

- Glass Epoxy

Glass Epoxy Sheet 3240 Trade Information

- Asia Australia Central America North America South America Eastern Europe Western Europe

- All India

Product Description

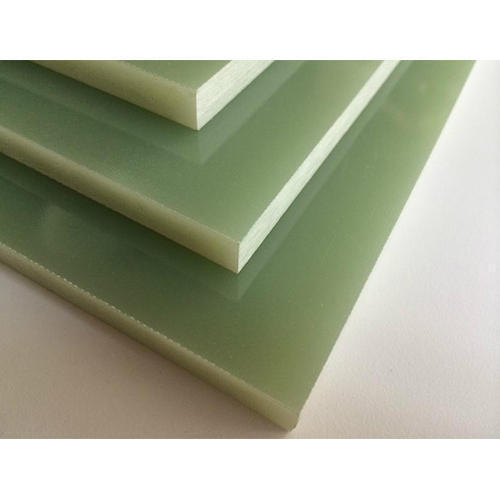

Glass epoxy sheet 3240, generally known as FR-4 (Flame Retardant 4), is a widely used thermosetting laminate material in the electronics and electrical industries. It is renowned for both its superior mechanical and electrical insulating qualities.

Glass Epoxy Sheet 3240 Features:

1. Glass epoxy sheet 3240 is made of woven glass fabric that has been treated with epoxy resin. Its exceptional qualities are the result of this mix.

2. This material's remarkable electrical insulation qualities are one of its key attributes. It is suitable for use in applications where electrical insulation is essential due to its high dielectric strength.

3. FR-4 is, as its name implies, flame retardant. It possesses self-extinguishing qualities, thus in the event of a fire, it won't aid in the spread of the flames. In applications where safety is a concern, this feature is essential.

4. High thermal resistance is a property of glass epoxy sheet 3240. It is suitable for use in heat-generating applications because it can resist reasonably high temperatures without significantly degrading its mechanical or electrical qualities.

5. This material has good dimensional stability and mechanical strength. Without breaking or cracking, it can bear mechanical stress and vibration.

6. FR-4 can be used in difficult locations where exposure to corrosive substances is a problem because it is resistant to numerous chemicals, including acids and solvents.

7. Due to its low water absorption, it can withstand prolonged exposure to moisture without losing its mechanical or electrical qualities.

Glass Epoxy Sheet 3240 Benefits:

1. Flexibility: Glass epoxy sheet 3240 is a flexible material that may be utilised in a variety of applications, such as printed circuit boards (PCBs), electrical insulators, transformers, and more.

2. Reliability: It is a dependable option for electrical and electronic components, delivering consistent performance over time because to its high electrical insulation and thermal resistance.

3. Safety: FR-4's flame-retardant qualities improve safety in applications where preventing fires is crucial.

4. Longevity: It has a long service life, which reduces the need for frequent replacements, thanks to its resilience to environmental variables and good mechanical qualities.

5. Cost-Effective: While it may initially cost more than certain other materials, its performance and longevity make it more affordable over time by lowering the need for maintenance and replacement.

6. Ease of Machining: FR-4 is practical for manufacturing and assembly operations because it is simple to machine, cut, drill, and shape to fulfil specific design requirements.

Frequently Asked Questions:

1. What is FR-4, or Glass Epoxy Sheet 3240?

Ans: A thermosetting laminate material constructed of woven glass fabric impregnated with epoxy resin is known as glass epoxy sheet 3240, also referred to as FR-4. It is a well-liked option in many industries thanks to its recognised mechanical and electrical insulating qualities.

2. For what purposes is Glass Epoxy Sheet 3240 mostly used?

Ans: Printed circuit boards (PCBs), electrical insulators, transformers, switchgear parts, and other electrical and electronic devices that require strong electrical insulation and mechanical robustness all employ FR-4 in some capacity.

3. Which advantages of employing Glass Epoxy Sheet 3240 are the most important?

Ans: Excellent electrical insulation, flame retardancy, high-temperature resistance, mechanical strength, chemical resistance, and less water absorption are just a few advantages of FR-4. Additionally, it is affordable, adaptable, and ideal for demanding environments.

4. What is the best way to build or machine Glass Epoxy Sheet 3240?

Ans: Using common tools and methods, like CNC machining, milling, and laser cutting, FR-4 can be easily machined, cut, drilled, and moulded. This fabrication flexibility enables exact customisation to satisfy certain design needs.

5. Is Glass Epoxy Sheet 3240 Safe for the Environment?

Ans: Because it contains epoxy resin, FR-4 is not naturally eco-friendly. To address environmental issues, attempts have been undertaken to provide eco-friendly substitutes. It can support sustainability in a variety of industries when used responsibly and recycled wherever practical.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese