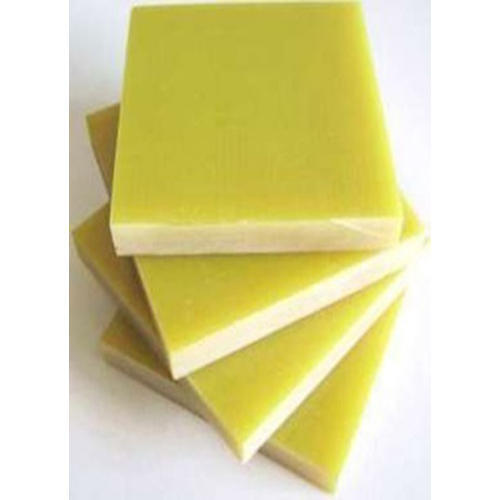

Insulation Sleeves

11 INR/Meter

Product Details:

- Product Type Insulation Sleeve

- Material Silicone and Polyurethane

- Thickness 0.25 to 1.40 Millimeter (mm)

- Application Electrical Insulation

- Color Black and White

- Click to view more

X

Insulation Sleeves Price and Quantity

- 3 Meter

- 11 INR/Meter

Insulation Sleeves Specification

- Insulation Sleeve

- Silicone and Polyurethane

- Electrical Insulation

- Black and White

- 0.25 to 1.40 Millimeter (mm)

Insulation Sleeves Trade Information

- 1000 Meter Per Month

- 7 Days

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India

Product Description

Insulation sleeves are protective covers made to insulate things from the heat and protect them from the elements, usually in the context of electrical or mechanical applications. They are frequently employed to stop heat loss, cut down on energy use, and improve safety by avoiding contact with hot or cold surfaces. Typically, good insulating materials like rubber, silicone, fibreglass, or different synthetic polymers are used to create these sleeves.

Insulation sleeves' key characteristics include:

1. Thermal Insulation: By reducing heat transfer between the object they cover and the environment, insulation sleeves are generally used to control temperature. They could aid in preserving a constant temperature and stopping energy loss.

2. Electrical Insulation: Insulation sleeves are used in electrical applications to shield connectors, cables, and wires from electrical currents and potential short circuits. They stop unintentional contact that may otherwise result in dangers like shocks or fires.

3. Mechanical Protection: Insulation sleeves provide defence against abrasion, physical harm, and environmental aggressors like UV radiation, chemicals, and moisture. This is especially crucial for outdoor or industrial applications.

4. Flexibility: The sleeves are frequently made to be adaptable and simple to install so that they can take on the contour of the object they are covering. They are excellent for a variety of applications due to their flexibility.

5. Variety: Insulation sleeves are available in a variety of shapes, sizes, and sizes to fit a range of objects and uses. Some sleeves are made for particular uses, such equipment protection, pipe insulation, or cable insulation.

6. Colour coding: Insulation sleeves may come in various colours for industrial settings or electrical applications, which can aid in identification, organisation, and safety compliance.

7. Heat Resistance: Insulation sleeves typically have a high heat tolerance, meaning they can survive high temperatures without losing their insulating effectiveness. This is particularly crucial in situations where heat plays a big role.

8. Simple Installation: To make installation simple, many insulating sleeves are built with features like closures, adhesives, or slip-on styles.

9. Environmental Considerations: Some insulation sleeves are made of eco-friendly materials and may also adhere to a number of safety and legal requirements.

Uses of Insulation Sleeves:

1. Electrical Wiring and Components: Insulation sleeves are frequently used in electrical systems to protect and insulate wires and cables. They help prevent electrical shocks, shorts, and fires by providing a barrier between conductive materials and external elements.

2. Automotive Applications: In vehicles, insulation sleeves are used to protect and insulate wiring harnesses, hoses, and pipes. They are essential for preventing damage from heat, chemicals, and abrasion.

3. Plumbing: Insulation sleeves can be used to insulate and protect pipes from extreme temperatures, especially in cold climates where they help prevent freezing. They are also used to protect pipes from corrosion and abrasion.

4. HVAC (Heating, Ventilation, and Air Conditioning) Systems: In HVAC systems, insulation sleeves are employed to insulate and protect refrigerant lines, air ducts, and other components from temperature variations, condensation, and external contaminants.

5. Industrial Machinery: In industrial settings, insulation sleeves are used to protect hoses, cables, and pipes on machinery from wear and tear, chemical exposure, and extreme temperatures.

6. Telecommunications: Telecommunication cables and wires are often insulated with sleeves to protect them from moisture, mechanical damage, and environmental factors.

7. Aerospace and Aviation: In the aerospace and aviation industries, insulation sleeves are used to protect and insulate wires, cables, and hydraulic lines on aircraft and spacecraft. They provide both electrical insulation and resistance to temperature extremes.

8. Medical Equipment: In medical devices and equipment, insulation sleeves may be used to protect wires, cables, and tubing from chemical exposure and mechanical damage.

9. Consumer Electronics: Insulation sleeves can be found in various consumer electronics, such as laptops, smartphones, and household appliances, to protect internal wiring and components.

10. Renewable Energy: In solar and wind energy systems, insulation sleeves are used to protect and insulate cables and wires connected to solar panels, wind turbines, and other renewable energy components.

11. Marine and Offshore: In marine and offshore applications, insulation sleeves are used to protect electrical and hydraulic systems from saltwater exposure, vibration, and harsh weather conditions.

12. Construction: In construction, insulation sleeves can be used for HVAC ductwork and plumbing to improve energy efficiency and protect against moisture buildup.

13. Fire Safety: Fire-resistant insulation sleeves can be used in applications where fire protection is critical, such as in fireproofing electrical cables and conduits.

14. Soundproofing: In some cases, insulation sleeves may also be used for soundproofing applications, providing acoustic insulation for pipes and ducts to reduce noise transmission.

FAQ:

1. Why are insulating sleeves advantageous in electrical applications?

Ans: The benefits of using insulation sleeves in electrical applications are numerous. By isolating conductors, they offer defence against electric shocks, short circuits, and arcing. They also extend the life and dependability of electrical systems by preventing impurities and moisture from impairing their integrity. Additionally helping with thermal management, insulation sleeves make sure that electrical components operate within acceptable temperature ranges.

2. Can insulating sleeves be utilised in both hot and cold environments?

Ans: Yes, insulating sleeves are adaptable and can be utilised in cold and hot environments. Whether the goal is to keep components warm or to prevent heat loss, they are made to provide thermal insulation by minimising heat transfer. Insulation sleeves can also shield wearers from extreme cold by avoiding the accumulation of frost and preserving constant temperatures.

3. How can I pick the appropriate sleeve size for my project?

Ans: The diameter or dimensions of the object you wish to cover should be measured in order to select the appropriate size of insulation sleeves. To achieve a snug fit without undue stretching, choose a sleeve with a slightly wider diameter. If unsure, go to the manufacturer's instructions or get in touch with a supplier for help choosing the right size.

4. Do various sectors have specific insulating sleeve needs?

Ans: Yes, there are many types of insulation sleeves designed for different industries. For instance, there are sleeves made for pipe insulation, automotive applications, aerospace components, cable and wire insulation, and so on. Each kind of sleeve is specifically designed to meet the specific needs of the industry for which it is intended, such as heat resistance, chemical compatibility, and mechanical protection.

5. Are insulating sleeves fire resistant?

Ans: The majority of insulating sleeves are made to be flame-resistant or fire-resistant. The materials used to create these sleeves can resist high temperatures without catching fire or assisting in the spread of flames. It's critical to find insulation sleeves that adhere to applicable fire safety standards and regulations when using them in applications that could present a fire risk.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese