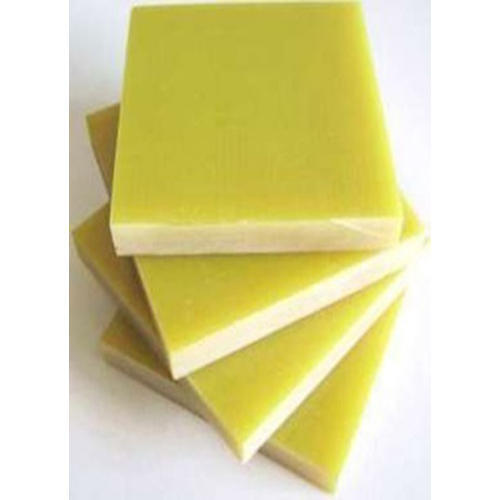

SMC Sheet

195 INR/Kilograms

Product Details:

- Size Standard

- Material Sheet Moulding Compound

- Thickness 1 Millimeter (mm)

- Application Industrial

- Breakdown Voltage 7 Volt (V)

- Color Grey

- Click to view more

X

SMC Sheet Price and Quantity

- 195 INR/Kilograms

- 100 Kilograms

SMC Sheet Specification

- Sheet Moulding Compound

- Industrial

- 1 Millimeter (mm)

- Grey

- 7 Volt (V)

- Standard

SMC Sheet Trade Information

- 1000 Kilograms Per Month

- 7 Days

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India

Product Description

The composite material known as SMC, or Sheet Moulding Compound, is utilised in a variety of sectors to create robust, lightweight, and long-lasting components. SMC sheets are created by mixing, heating, and moulding a mixture of polyester resin, chopped glass fibres, and other components into the necessary forms. SMC sheets are frequently utilised in applications where great mechanical strength, electrical insulation, and resilience to different environmental conditions are necessary.

Characteristics of SMC sheets:

1. Composite Material: Polyester resin serves as the matrix material for SMC sheets, which are then reinforced with glass fibres that have been chopped. These fibres provide the composite its mechanical sturdiness and rigidity.

2. Mechanical Strength: SMC sheets have strong mechanical qualities, including high tensile strength, flexural strength, and resistance to impact. They are suitable for applications that call for structural stability and load-bearing capacity because of these characteristics.

3. Electrical Insulation: SMC sheets naturally have the ability to conduct electricity, which makes them suited for use in the electrical and electronics industries. To assure safety and avoid electrical risks, they are employed in the production of enclosures, cabinets, and housings for electrical equipment.

4. Resistance to Corrosion: SMC sheets have a high level of corrosion resistance. This includes resistance to UV radiation, chemicals, and moisture. They are suited for outdoor applications and places where exposure to harsh circumstances is a concern because of their resistance.

5. Lightweight: Compared to their typical metal equivalents, SMC sheets are comparatively lightweight yet having a high mechanical strength. This function helps to increase energy efficiency, make things easier to handle, and cut down on transportation expenses.

6. Flexibility: SMC sheets may be moulded into intricate shapes and designs, which gives them design flexibility. Due to the integration of multiple functions and components into a single element, this design flexibility eliminates the need for assembly.

7. Automobile and Aerospace: SMC sheets are used in the production of body panels, hoods, spoilers, and interior pieces in the automobile and aerospace industries. In many industries, its combination of lightweight design and structural integrity is advantageous.

8. Construction and infrastructure: SMC sheets are also employed in the production of goods like manhole covers, utility boxes, and access panels in the construction and infrastructure industries. They are appropriate for these applications because to their strength and resilience to environmental conditions.

9. Recyclability: Some SMC materials are made to be recyclable, helping to promote sustainability and lessen the negative environmental effects of producing composites.

FAQ:

1. What Is SMC sheet?

Ans - The composite material known as SMC, or Sheet Moulding Compound, is made of polyester resin, finely chopped glass fibres, and additives. It is produced using a compression moulding method that involves mixing these components, heating, and compressing the resulting mixture in a mould to produce solid, high-strength sheets or components.

2. Why are SMC sheets useful in manufacturing?

Ans - To name a few advantages, SMC sheets have outstanding electrical insulating qualities, high mechanical strength, lightweight construction, corrosion resistance, and design flexibility. These characteristics make them excellent for a variety of uses in the construction, electrical, automotive, and aerospace industries.

3. How do the electrical and electronic sectors use SMC sheets?

Ans - Due to their innate electrical insulating qualities, SMC sheets are used to create enclosures, cabinets, and housings for electrical equipment. The safety of users and equipment is ensured by these components, which offer protection against electrical risks.

4. Can I use SMC sheets outdoors?

Ans - As a result of its resilience to external elements like dampness, chemicals, and UV radiation, SMC sheets are suitable for outdoor applications. They are perfect for products like manhole covers, utility boxes, and other infrastructure components because of their resilience.

5. SMC sheet recycling: Is it possible?

Ans - As a result of their recyclable design, several SMC materials support environmental sustainability initiatives. However, the SMC's unique composition and the available recycling procedures may have an impact on the recyclability. For detailed information on recyclability, it's crucial to speak with manufacturers or recycling facilities.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese