- Home Page

- Company Profile

-

Our Products

- Fiberglass and Insulation Sleeves

- Polyester Expandable Braided Sleeves

- Fire Resistant Sleeve

- Insulation Sleeves

- SRBP Tubes

- Polyurethane Fiberglass Sleeves 1.5 kv

- Varnished Fiberglass Sleeve F Class

- Acrylic Fiberglass Sleeving

- Fire Sleeves

- Polyurethane Fiberglass Sleeve

- PVC Coated Fiberglass Sleeve

- Silicone Coated Fiberglass Sleeve

- Polyurethane Coated Fiberglass Sleeves

- Fiberglass Sleeve ( China Sleeve )

- Fiberglass Sleeving B Class

- Nomex Paper and Electrical Insulation Papers

- Electrical Insulating Paper

- Laminated Fleece Paper

- Pure Aramid Paper

- Eurotherm Laminated Nomex Paper NPN

- Saturated Fleece Paper

- Laminated Aramid Paper

- DuPont Nomex Paper

- Saturated Fleece Paper

- Insulating Kraft Paper

- Insulation Pressboard

- Laminated Nomex

- Electrical Insulation Papers and Laminates

- Pure Aramid (Nomex) Paper

- Laminated Fleece

- Black Kraft Paper

- Amotforse Brown Kraft Paper

- Diamond dotted Paper

- Fiberglass and Insulated Cables

- Glass Epoxy Sheets and Wedges

- Varnishes and Thinners

- Electrical Insulation Tapes

- Electrical Insulation Sheets and Fabrics

- PTFE Wire

- Silicon Cable

- Insulation Film

- Fiberglass and Insulation Sleeves

- Certificates

- Contact Us

Acrylic Fiberglass Sleeving

10.0 INR/Meter

Product Details:

- Density Industrial standard Gram per cubic centimeter(g/cm3)

- Surface Treatment Acrylic Resin Coated

- Layer Single braided fiberglass with uniform acrylic coating

- Coating Type Acrylic resin, heat-cured

- Product Type Insulating Sleeve

- Material Braided Fiberglass with Acrylic Resin Coating

- Tensile Strength High mechanical strength with flexibility Newtons per Millimetre Squared (N/mm2)

- Click to view more

X

Acrylic Fiberglass Sleeving Price and Quantity

- 10.0 INR/Meter

- 1 Meter

Acrylic Fiberglass Sleeving Specification

- As required Millimeter (mm)

- Insulating Sleeve

- Industrial standard Gram per cubic centimeter(g/cm3)

- Up to 7 kV Volt (V)

- Acrylic Resin Coated

- Features: Class F (155 C) heat resistance Excellent dielectric strength Smooth surface for easy installation Resistant to oil, varnish, and moisture Flexible and durable Usage & Applications: Motors, transformers, and generators (lead wire insulation) Wiring harnesses in appliances and automotive industry Industrial equipment and lighting fixtures General-purpose electrical insulation

- 0.2 mm 2.5 mm (depending on size) Millimeter (mm)

- White, Black, Brown, Customized

- Braided Fiberglass with Acrylic Resin Coating

- High mechanical strength with flexibility Newtons per Millimetre Squared (N/mm2)

- Low, excellent thermal insulation Watt/Meter/K (w/(m.k)

- 155 C (Class F Insulation)

- Single braided fiberglass with uniform acrylic coating

- Acrylic resin, heat-cured

Acrylic Fiberglass Sleeving Trade Information

- 3 Days

- Middle East, Eastern Europe, Western Europe, Australia, Central America, Africa, Asia, North America, South America

- All India

Product Description

Acrylic Fiberglass Sleeve High Performance Electrical Insulation

Acrylic Coated Fiberglass Sleeving (also known as Acrylic FG Sleeve) is a premium-grade insulating sleeve made by braiding high-quality fiberglass yarn and coating it with a durable acrylic resin. This combination provides excellent electrical insulation, thermal resistance, and mechanical durability, making it an ideal choice for motors, transformers, and wiring harnesses.

Construction

-

Base Material: Braided alkali-free fiberglass yarn

-

Coating: Heat-treated acrylic resin

-

Finish: Smooth, glossy, and flexible surface

-

Color Options: Natural white, black, brown, or customized

Technical Properties

-

Operating Temperature: -40C to +155C (Class F insulation)

-

Breakdown Voltage: 1.5 kV 7 kV (depending on wall thickness)

-

Dielectric Strength: High and stable even under heat and moisture

-

Flame Resistance: Self-extinguishing properties after removal of flame source

-

Tensile Strength: High flexibility with good mechanical resistance

-

Chemical Resistance: Resistant to oils, varnishes, moisture, and most industrial solvents

-

Sizes: Available from 0.5 mm to 25 mm diameter (custom sizes available)

Key Features

-

Provides Class F (155C) thermal protection

-

Strong electrical insulation with reliable performance

-

Smooth surface for easy wire insertion and bundling

-

Maintains flexibility without cracking under bending

-

Resistant to heat, abrasion, and chemical exposure

-

Long service life in both domestic and industrial applications

Applications

Acrylic Fiberglass Sleeves are widely used in:

-

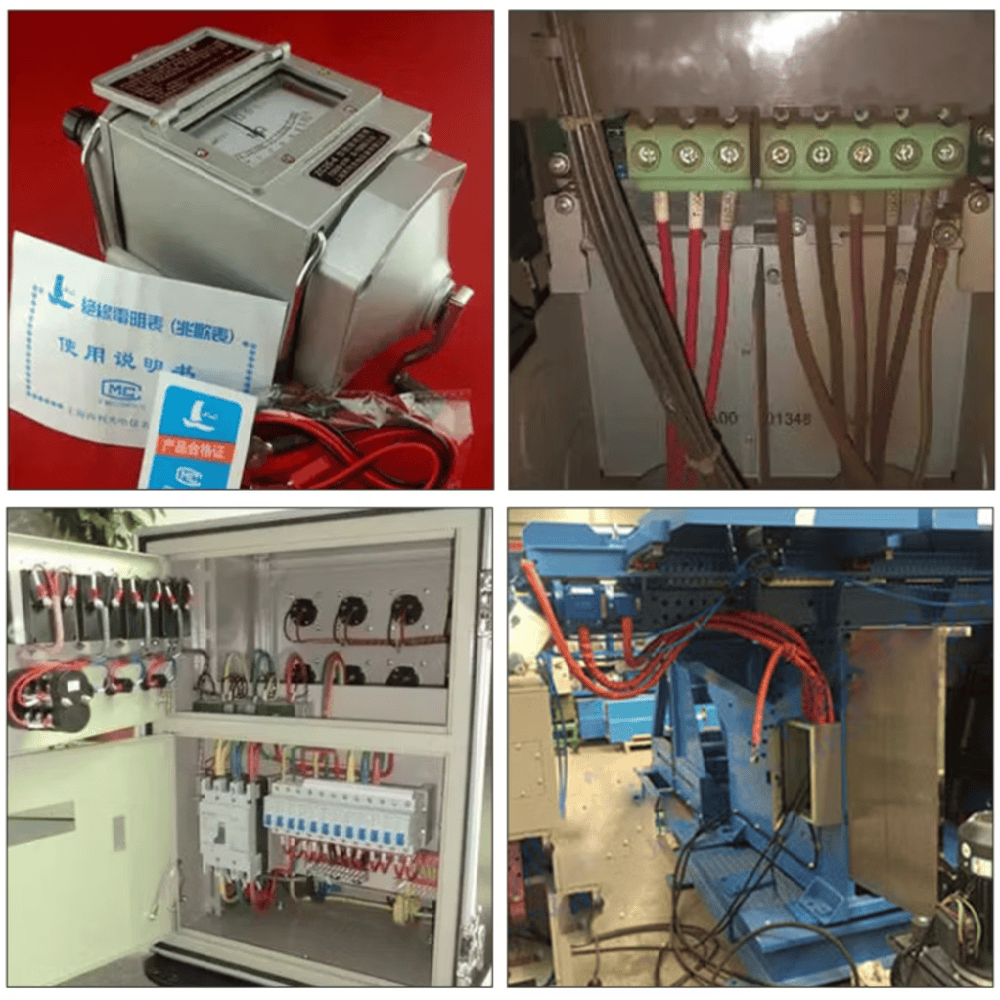

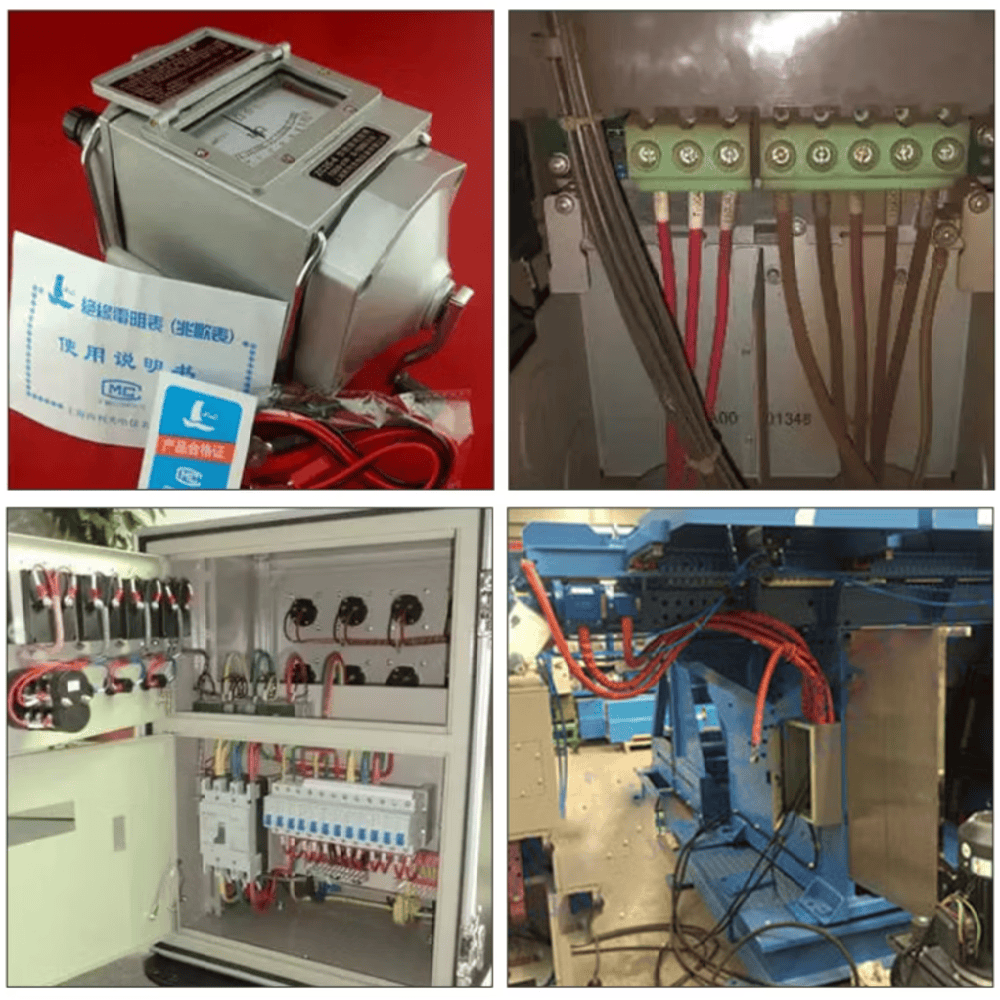

Electrical Motors for winding lead insulation and protection

-

Transformers and Generators for lead wire and terminal insulation

-

Wiring Harnesses in automotive, appliances, and electronics

-

Lighting Fixtures and Panels as a protective sleeve for high-voltage wires

-

Industrial Equipment for added insulation in harsh environments

Why Choose Acrylic FG Sleeves?

Compared to PVC-coated sleeves, Acrylic FG Sleeves offer higher temperature resistance (Class F) and improved dielectric strength. While not as heat-resistant as Silicone sleeves, they provide an excellent balance of performance, durability, and cost-effectiveness.

Superior Mechanical and Electrical Performance

This sleeving combines the strength and flexibility of braided fiberglass with the protective qualities of an acrylic resin coating. Its uniform surface ensures reliable electrical insulation, mechanical protection, and ease of handling during installation. The single-layer structure further enhances flexibility, making it suitable for curved or compact wiring environments.

Industrial Versatility and Customization

Acrylic Fiberglass Sleeving is favored across multiple industries, from automotive to electrical manufacturing. It can be customized by width and color and withstands high operational stresses while providing long-lasting insulation. The products adaptability and excellent resistance to oil, chemicals, and thermal extremes make it a staple in motor leads, transformer connections, and complex wiring harnesses.

FAQs of Acrylic Fiberglass Sleeving:

Q: How is acrylic fiberglass sleeving typically used in industrial and electrical applications?

A: Acrylic fiberglass sleeving is extensively utilized for insulating and protecting wiring in motors, transformers, generators, and wiring harnesses within appliances and automotive assemblies. Its Class F (155C) heat resistance enables it to perform reliably in high-temperature and high-voltage environments, making it ideal for lead wire insulation and general-purpose electrical applications.Q: What are the main benefits of using this sleeving for electrical insulation?

A: The main benefits include excellent dielectric strength (up to 7 kV breakdown voltage), high flexibility, resistance to oil, varnish, and moisture, and reliable thermal insulation. These properties ensure long-term electrical safety, easy installation, and durability in harsh industrial conditions.Q: When should I choose acrylic fiberglass sleeving over other types of insulation?

A: Choose acrylic fiberglass sleeving when you require high mechanical strength, superior flexibility, and resistance to heat, chemicals, and abrasion. Its especially suitable for environments demanding up to 155C thermal resistance and applications needing smooth, easily installable insulation.Q: Where is the best place to apply this sleeving in a manufacturing environment?

A: This sleeving finds its optimal use in motors, transformers, generators, wiring harnesses, and industrial electrical panels. It is also highly recommended for use in appliance connections and automotive wiring systems where protection against mechanical wear, moisture, and elevated temperatures is essential.Q: What is the process of installing acrylic fiberglass sleeving?

A: Installation involves cutting the sleeving to the required length, slipping it over the wires, and ensuring a snug fit. Its smooth, flexible finish allows for straightforward placement, including over bends and connectors, reducing installation time while ensuring consistent insulation.Q: How does the acrylic resin coating enhance the properties of the fiberglass sleeving?

A: The heat-cured acrylic resin coating stabilizes the fiberglass braid, providing a glossy, abrasion-resistant surface that resists cracking and moisture ingress. It also contributes to the sleevings high dielectric and mechanical strength, prolonging service life and maintaining insulation integrity under stress or temperature fluctuations.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Email

Send Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese